yup, this is REALLY really a late post by me ("~.~) mianhae..as i've already got my result for this FINAL YEAR PROJECT 1 on the last week and guess what??! i've successfully got A for this course! yeahhh yeahhh...it clearly paid our sweat and time during the completing of this project. (actually it is an individual project but the things are related to each other so, my colleagues and I have to do it together~)

in the other word, i've worked directly with my IIUM bestie ever a.k.a coursemate@classmate a.k.a sifu a.k.a cik NURUL SYAFIQAH tersayang ^^ and indirectly with encik KUDOU (haha..should included you as you are one of my reader here!)

ok obviously, i don't really like to ramble about my studies here..sorry for that because i just think that you guys aren't interested in this whole engineering stuff but this post is a MUST since I LOVE MY F.Y.P PROJECT so much and i did gave my very BEST towards it and at the end, it is full of satisfactory! ^^ Alhamdulillah...

so, my manufacturing engineering F.Y.P 1 tittle is " HEAT ASSISTED OF DIE MACHINING SKD 11 STEEL " . honestly, when we've been given this tittle i was like..Oh, apekah itu?!? haha..then as time goes by we've slowly getting it since there were several meeting with the supervisor and LOTS of journal reading and LOTS of literature review were done related to this project!

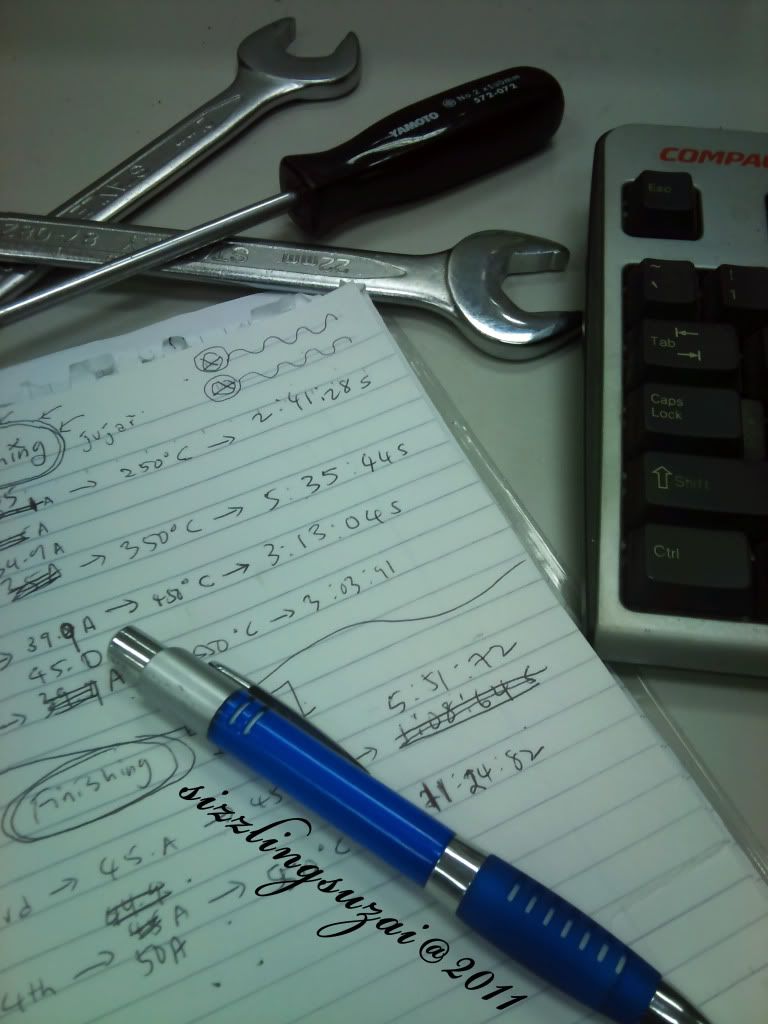

now, let me story a bit about what we've been struggling during the whole experiment. this is the hot machining of die for a roughing and finishing process, means that we've to used the EDM Milling Machine to cut the part and the Induction Heat System to provide the hot temperature in the range of 250 Degree Celsius to 550 Degree Celsius.

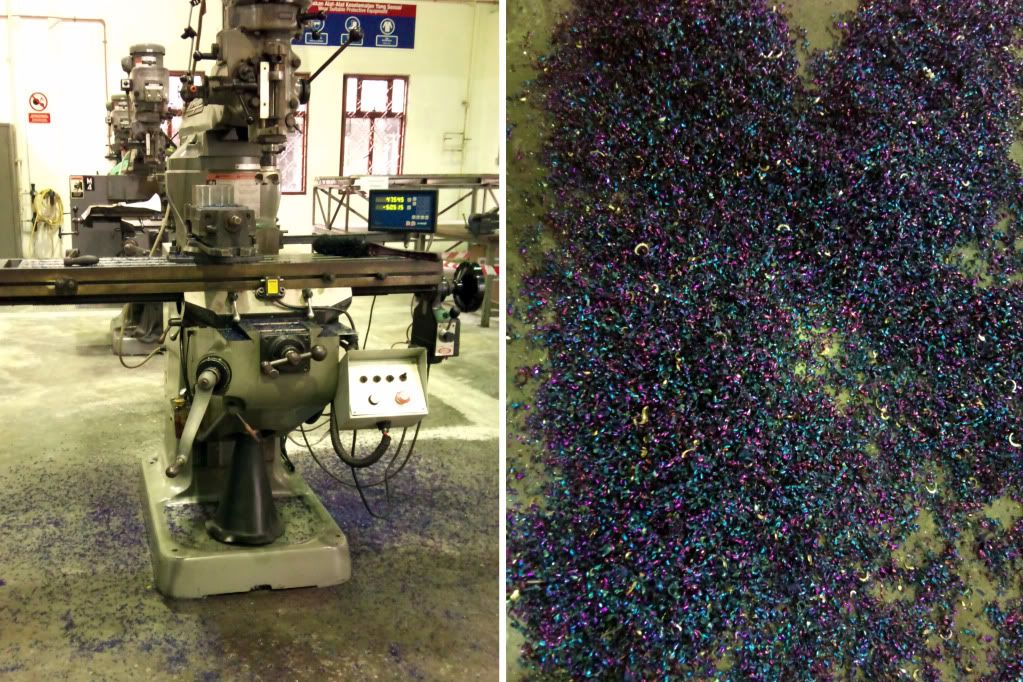

our workpiece is one of the hardest material called as SKD 11 STEEL. at first, we've to do some leveling here by using this manual milling machine in the workshop in order to make sure all the surfaces are in the same level and smooth.

as we started the cutting process, i stunned by the beautiful purple + blue chip that produced by the material. yup, that thing in the above image (right) is called as chip. haha..so that, i've been told that almost of all the chip produced by a steel is in purple colour. Waahh..machining can be as interesting as this, OK ("^^)

HAHA..this is not a RESTING time but it is a SETTING or initial process of the machine before we can start the real machining. yup, we look like a PRO here since we've done it several times to get the ACCURATE height of the induction heating system that should be attached to this EDM milling machine. (~"`~)

as you can see in the left image, the coil besides the cutter should be in the range of 5mm-10mm. otherwise, it will effect the heating process and the workpiece and of course the result of the whole experiment.

Now, this is the HARDEST part where we've been spending the most of the time on it. we've even stayed in the lab from 9 a.m to 11 p.m! huh..it is really a tiring week when we've to deal with the damage coil, a leaking preheating system and wondering of NOBODY know about how to operate that preheating system until some outsider came and teach us! =( terima kasih pakcik from Aircoat Company!

then, again we've faced huge difficulty on the clamping of the workpiece and also the ZERO setting for the cutter. unfortunately, both of the aspects are very important as it will absolutely effect the result of the vibration analysis as well as the surface analysis later on.

ok, eventually we've done the experiments with some errors. However, we still have to finish up the whole report as the submission date is fixed or else you will not getting any mark and you are not qualify to present and yup, YOU HAVE TO REPEAT THE WHOLE COURSE again! hahaha..so it's better than nothing!

now, this is the scariest part for all the FYP's students, the presentation day! hehe..honestly i'm the person who LOVE TO TALK, either with my clan or in front of the public HAHA AS LONG AS i understood enough about the things that i'm gonna present. (^_____^) seriously guys, DON'T BE SCARED OF PRESENTATION just understand the subject well and be confident, then you can conquer the stage!

thus, i think we had enough here or if there is somebody who is interested in our project or has anything to inquiry about the procedure of using the EDM Milling Machine and the Induction Heating System, you are welcome to ask because THERE WAS SO HARD TO FIND AN INSTRUCTOR to teach us on how to use both machines especially the Preheating System. therefore, it will be my pleasure IF I CAN help to less your burden. ("^^) sharing is caring!

lastly, TQ for reading my summary of the FYP 1 report here... ^^

2 Comments

wah..hebatnyer dpt A.. tahniah...

ReplyDeletetq so much babe! xd la hebat kak just terbayar la sgl peluh penat lelah fyp 1 ni kn..alhamdulillah heheh..but still we've get 2 b ready for the fyp 2 plak kak ^^

ReplyDeleteThank you for coming by.

Comments are your responsibility.

Any comments are subjected to the Act 588 MCMC 1988.

Comment wisely, and do it with pure intentions.

Thanks for reading!